News Information

Pay attention to Woaffom Textile, we will update the company dynamics and related product knowledge for you at any time.

Causes and solutions of denim loose edges

- Categories:Company News

- Time of issue:2020-08-31 23:43

(Summary description)The loose edge of denim not only affects the opening efficiency of the loom, but also causes great troubles to the subsequent finishing process. If this problem is not solved well, it will not only seriously affect the appearance of the denim during the rolling and forming process, but also rotten edges, curling and peeling may occur, which will seriously affect the product quality, especially in the desizing and mercerizing process. Happening.

Causes and solutions of denim loose edges

(Summary description)The loose edge of denim not only affects the opening efficiency of the loom, but also causes great troubles to the subsequent finishing process. If this problem is not solved well, it will not only seriously affect the appearance of the denim during the rolling and forming process, but also rotten edges, curling and peeling may occur, which will seriously affect the product quality, especially in the desizing and mercerizing process. Happening.

- Categories:Company News

- Time of issue:2020-08-31 23:43

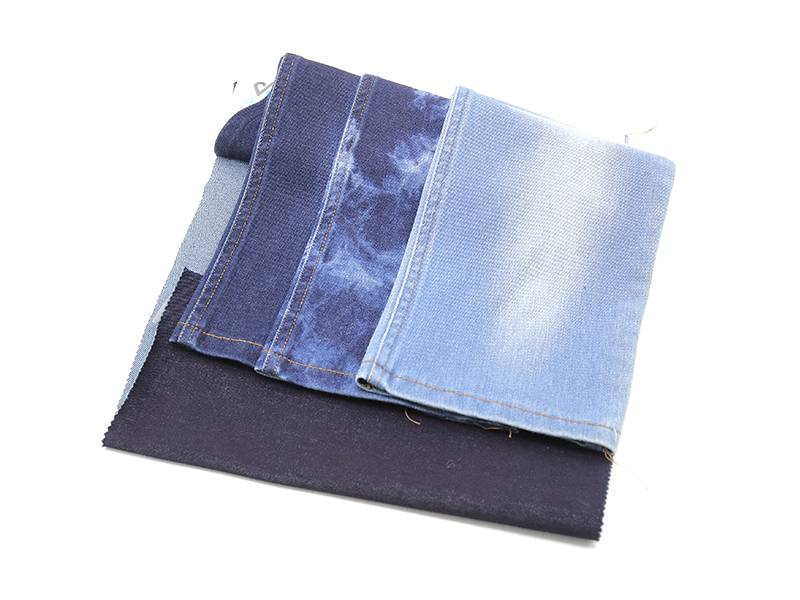

- Views:

The loose edge of denim not only affects the opening efficiency of the loom, but also causes great troubles to the subsequent finishing process. If this problem is not solved well, it will not only seriously affect the appearance of the denim during the rolling and forming process, but also rotten edges, curling and peeling may occur, which will seriously affect the product quality, especially in the desizing and mercerizing process. Happening.

1. Analysis of factors affecting loose edge

According to the technological process of denim, the processes that affect the loose edge of denim mainly include warping process, sizing process and weaving process. The appropriateness of the warp tension control at the edges of these processes not only affects the efficiency of the loom, but also affects the appearance quality of the cloth surface. How to control the tension of the side yarn, choose a good side structure, and adjust the width of the weaving shaft is the key to solving the loose edge. In view of the above factors, the following measures have been taken to adjust the tension of the edge yarns and properly solve the problem of edge yarn slack.

2. Loose Edge Solution

2. 1 Warping process

Most of the warping of denim yarn is batch warping. In order to prevent the colored strips of the weaving shaft and the color difference in the edges, the tension of the same warp beam must be uniform, and the warp winding tension of the same cylinder yarn must be consistent.

2. 2 Dyeing process

The sizing process is to dye the warp yarns of multiple warp beams that have been warped through the sizing and dyeing combined machine to dye the color required by the process design, and to improve the weaveability of the warp yarns by sizing the warp yarns.

2. 3 Weaving process

The factors and solutions that cause loose edges in the weaving process are mainly as follows:

(1) The influence of the weak selvedge. All selvedge selvedge devices of the loom are independent selvedge, which is very convenient for adjusting the tightness of cloth selvedge. However, due to the poor tightness of the cloth edges of the shuttleless loom, improper adjustment of the hem will cause the cloth edges to become loose and the yarns to be loose. Usually single-sided double seaming is used, which effectively solves the phenomenon of loose edges and keeps the edges tight.

(2) The influence of weaving shaft width. Too large or too small weaving shaft width will cause an included angle between the side warp and the ground weave warp, resulting in increased friction between the side warp and the reed, resulting in unexpected elongation of the side warp, and frequent side yarn formation Broken ends or loose yarn.

Scan the QR code to read on your phone

Relevant Information

-

Causes and solutions of denim loose edges

The loose edge of denim not only affects the opening efficiency of the loom, but also causes great troubles to the subsequent finishing process. If this problem is not solved well, it will not only seriously affect the appearance of the denim during the rolling and forming process, but also rotten edges, curling and peeling may occur, which will seriously affect the product quality, especially in the desizing and mercerizing process. Happening. - What is so special about knitted denim ? 08-31

- Finishing of knitted denim fabric 08-31

Product Search

Hot key words: Knitted denim fabric Fancy denim yarn Indigo

- Products

- Knitted denim fabric

- Fancy denim yarn

Copyright © 2020 Changzhou Waffom Textile Co., Ltd. All Rights Reserved 京ICP證000000号

Powered by:www.300.cn IPv6 is supported6

Follow Waffom

Follow Waffom

Follow Waffom

Follow Waffom